Manufacturing Process

Veneer

We source our logs from regulated forests in Austria ensuring compliance with sustainability standards set by the Austrian Forest Act. Each veneer has been sliced and processed to have the best visual and top structural quality.

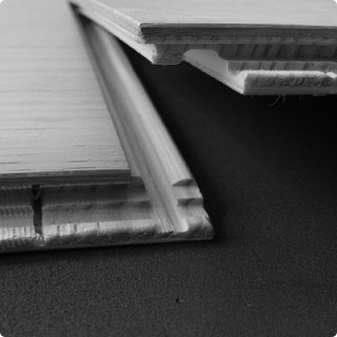

The Click

Our precise milling machines have allowed us to create a proprietary mechanical locking system for our floors. More than 80% of Engineered wood flooring here in Europe is installed with a mechanical locking system (Click system). This method of installation is rapidly growing in North America.

In general, the reasons for the growth of clicking systems are found in the benefits for the installer and advantages over alternative systems:

- Convenience and ease of installation

- Speed of installation

- No need for accessory materials such as adhesive, or fasteners such as staples.

- Ergonomically less strenuous.

- The precision is built into the product normally lowering the risk of error.

- Can be installed over most flooring except carpet.

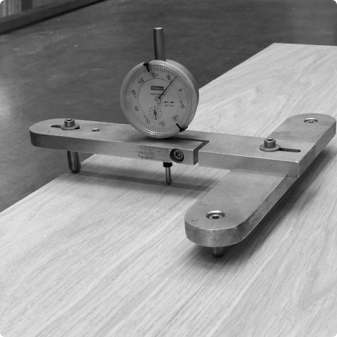

Finishing

After the planks are sanded, they go through the process of wire brushing. The wire brush removes the soft wood and creates the texture on the surface of the floors. We stain the floors with precision to insure we maintain the color consistency. The floor is then finished with 5 layers of super matte German-made poly urethane. That is 5 layers of protection!